Brake System Of A Mill Machine Process Of Gravity Separation Of Iron Ore

.jpg)

Breakage process of mineral processing comminution machines

2020年9月1日 Several investigations showed that mineral liberation degree could be affected by ore texture and/or loading mechanisms However, varied definitions have been used for the breakage fundamentals as the leading cause of mineral liberation This review identifies the 2022年1月1日 This chapter introduces the principle of how lowgrade iron ores are upgraded Physical separation of iron ore: magnetic separation2024年4月1日 Iron ore tailings (IOTs) are byproducts generated during the beneficiation A critical review on metallurgical recovery of iron from iron ore Six steps to process iron ore 1 Screening We recommend that you begin by screening the The six main steps of iron ore processing Multotec

Beneficiation of LowGrade Hematite Iron Ore Fines by

2023年9月7日 ABSTRACT: Present investigation includes the magnetizing roasting of low 2024年2月8日 Researchers have investigated the beneficiation of fines by a sequential process involving gravity separation, followed by magnetic separation, and concluding with flotation and have shown the possibility to improve the Beneficiation of LowGrade Hematite Iron Ore 2018年9月25日 concentration, density, gangue material, gravity separation, iron ore beneficiation, Jig, Jigging, Low grade iron ore, Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting Low grade Iron Ore Beneficiation and the 2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient lowquality iron ore beneficiation to meet steelmaking quality requirements This comprehensive review explores Exploring LowGrade Iron Ore Beneficiation Techniques: A

.jpg)

Developments in the physical separation of iron ore:

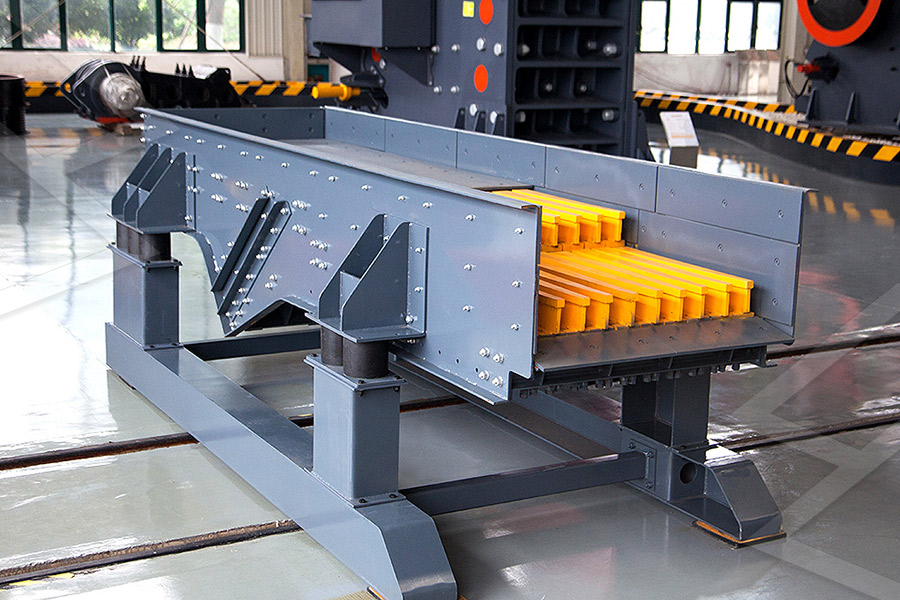

2015年1月1日 For lowgrade iron ore separation, it is very important to develop an optimized flow sheet to achieve the best iron concentrate grade and iron recovery while keeping the cost as low as possible Gravity separation also has the advantage of low operating costs, but it is often implemented at a much smaller scale compared with magnetic 2019年7月24日 During the gravity separation process, the ore particles are subject to gravity (if the process takes place in centrifugal force field, centrifugal force is the main force), mechanical forces exerted by the equipment and the force of the mediumThe ingenious combination of these forces makes the different density of the ore particles produce Comprehensive Guide of Gravity Separation Method2020年9月23日 Gravity concentration or in other word this process is also known as gravity separation This process is applicable for those ores in which principle metals have higher density as compared to their gangue and other earthy impurities The specific gravity of iron ore is higher than its gangue The specific gravity of common iron ores areBENEFICIATION OF LOW/OFF GRADE IRON ORE: A 2020年4月1日 Preheat treatment of chromite ore plays a vital role in gravity separation The optimized tabling conditions suggested by BBD are 8° tilt angle, 4 L∙min1 water flow rate and temperature for Process optimization of a chrome ore gravity concentration

.jpg)

(PDF) Effective Beneficiation of Low Grade Iron Ore

2008年1月1日 Gravity separation by jigging to produce highergrade iron ore products has been practiced for many decades (Miller 1991(Miller , 2003 and is a potential technology for beneficiating difficultto 2022年1月1日 The ore is mainly composed of magnetite, hematite, martite, and quartz It is very difficult to produce a high quality iron ore concentrate by magnetic separation alone for this type of iron ore The feed ore is first ground using ball mills down to about 90% −75 micron particle sizePhysical separation of iron ore: magnetic separation2022年1月1日 Iron ore is one of the main raw materials to make steel About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BFBOF) route or through the electrical arc furnace (EAF) route The majority of world crude steel is made from the BFBOF minution and classification technologies of iron ore2020年12月1日 In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied The Run of Mine (ROM) sample assayed 2191 % Fe, which is very low grade in nature(PDF) Beneficiation and flowsheet development of a low grade iron ore

Optimization of a primary gravity separation treatment for

2014年4月11日 Vegetable oil refinery wastewaters (VORW) are loaded with organic and oily matter, and cannot be decontaminated by conventional treatment methods Pretreatment methods with the objective of decreasing oil and grease (OG) and chemical oxygen demand (COD) content either generate hazardous byproducts or may be too costly In this paper, it is 2022年2月28日 Gravity separation is a method in which materials/minerals are separated based upon the difference in particles density []Water as a medium is an important factor in improving the differential movement between various particles during gravity separation and eventually sorting different particles []When water is removed, and air plays the role of separation Gravity Separation SpringerLink2023年2月15日 Hematite, also spelled haematite, is a weakly magnetic iron ore with better floatability than magnetite and wide distributionIt is one of the most important raw materials for the extraction of iron Its composition is complex How to Extract Iron from Hematite: Methods and 2017年1月1日 Finally, the magnetic component of the roasted ore can be recovered by magnetic separation after being liberated from gangue minerals Many pilotscale suspension magnetizing roasting and magnetic Recovery and separation of iron from iron ore using

.jpg)

The Beginner's Guide to Gravity Separation Miningpedia

2022年11月28日 1 Advantages Compared with other separation methods, gravity separation has the following advantages: (1) The gravity separation method has a wide range of applications, and the particle size range of the material that can be processed is wide, up to several hundred millimeters in thickness and up to 001 mm in fine;2021年6月26日 Today, I will share with you the magnetic separation process of iron ore Magnetic Separation Principle Magnetic separation is a beneficiation method that uses the magnetic difference between minerals in a nonuniform magnetic field to separate different minerals Magnetic separation is the most commonly used beneficiation method for ferrous Process and Principle of Magnetic Separation of Iron Ore2024年9月29日 Iron fillings from sulphur Gravity Separation We use this process for the separation of a mixture having components of different densities The powdered mixture undergoes with a stream of running water The lighter components wash away with water, leaving the heavier ones For example, a separation of gold particles from rocky substances Methods of Separation of Mixtures with Examples Scienly2016年5月24日 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring Beneficiation of Iron Ore 911Metallurgist

.jpg)

(PDF) Flotation of Iron Ores: A Review ResearchGate

2019年11月19日 The aim of this paper is to provide a welldetailed, wellreferenced source for the current status of iron ore flotation, and thus provide a useful guide to its future development and to further 2022年12月1日 1 Introduction Iron ore pellets are one of the significant sources of iron for iron and steel making due to their superior metallurgical performance, low energy consumption, and less emission of environmentally harmful dust and gases during the production process [1], [2], [3]The two primary raw materials for pellet production are hematite and magnetite concentratesMechanism of magnetite iron ore concentrate morphology 2021年11月2日 A dry densitybased fluidized bed separator was used to beneficiate coarse particulate iron ore The atomized iron powder and zircon sand, with specific size fractions of 150–75 and 250–150 A novel dry gravity separation method for cleaner 2020年5月6日 GRAVITY CONCENTRATION OF IRON ORE R K Rath and R Singh INTRODUCTION Gravity concentration process is the oldest beneficiation method known to mankind This is a physical process and exploits the differences in densities of minerals to bring about a separationCHAPTER7 GRAVITY CONCENTRATION OF IRON ORE

.jpg)

Gravity Separation in Mining: Techniques and

2024年1月29日 The content provides a comprehensive overview of gravity separation in mining processing, covering various techniques Skip to content 22 Oct 2024 Pit Optimization Process: Economic and Technical Analysis 6 2024年6月18日 The braking process is simulated on the dry runway, the results show that the EBA system can complete the braking task of the commercial aircraft flight tests and iron bird tests are considered to verify the model and simulation results The EBA braking process could be researched under special situations, such as wet runway, bumpy runway Slipping Analysis on the Braking Process of a Commercial2022年3月1日 Typically, separation at crushing sizes is labelled preconcentration, during which waste material is removed during the early stage of the comminution process Separation at grinding sizes, typically referred to as the concentration stage, is carried out with a view to producing a highgrade product (Sousa, 2020)A systematic review of sustainable gold extraction from raw 2023年9月18日 Depending on the required release and the iron concentration, this process is repeated two or three times This way, spiral gravity separation is carried out in iron ore processing Wondering about spiral gravity separation or any other mining iron ore process? Contact us today to solve all your doubts Magnetic DivisionTop 6 Steps Of Iron Ore Processing Australian Mining

Developments in the physiochemical separation of iron ore

2015年1月1日 Table 111 shows the points of zero charge (pzc's) for some iron oxides and quartz (Aplan and Fuerstenau, 1962)This property is important when using flotation collectors that are physically adsorbed, for example, amines The pzc's for the three iron oxides, hematite, magnetite, and goethite, are around neutral pH (~ pH 7), whereas the pzc for quartz is in the 2022年1月1日 The first SLon2500 vertical ringpulsating high gradient magnetic separator was designed and built up in 2006 It was installed at the tails dam of Hai Nan Iron Mining Company to recover iron Physical separation of iron ore: magnetic separation2023年1月20日 The ore belt of shaking table has the functions of characterizing the shaking table control parameters and analyzing the processing state Therefore, the study of the feature extraction of the ore Research on optimization of control parameters of gravity2017年3月12日 PDF Gravity separation is an industrial method of separating two components, either in suspension, or in dry condition, from a granular mixture Find, read and cite all the research you need (PDF) GRAVITY SEPARATION IN ORE DRESSING ResearchGate

.jpg)

Low grade Iron Ore Beneficiation and the

2018年9月25日 concentration, density, gangue material, gravity separation, iron ore beneficiation, Jig, Jigging, Low grade iron ore, Low grade Iron Ore Beneficiation and the Process of Jigging Iron ore resources are getting 2024年8月2日 The beneficiation of lowgrade iron ores is a key research and development topic in the mineral processing industry The gradual exhaustion of highgrade iron ore reserves, and rising consumer iron and steel demand globally necessitate efficient lowquality iron ore beneficiation to meet steelmaking quality requirements This comprehensive review explores Exploring LowGrade Iron Ore Beneficiation Techniques: A2015年1月1日 For lowgrade iron ore separation, it is very important to develop an optimized flow sheet to achieve the best iron concentrate grade and iron recovery while keeping the cost as low as possible Gravity separation also has the advantage of low operating costs, but it is often implemented at a much smaller scale compared with magnetic Developments in the physical separation of iron ore: 2019年7月24日 During the gravity separation process, the ore particles are subject to gravity (if the process takes place in centrifugal force field, centrifugal force is the main force), mechanical forces exerted by the equipment and the force of the mediumThe ingenious combination of these forces makes the different density of the ore particles produce Comprehensive Guide of Gravity Separation Method

BENEFICIATION OF LOW/OFF GRADE IRON ORE: A

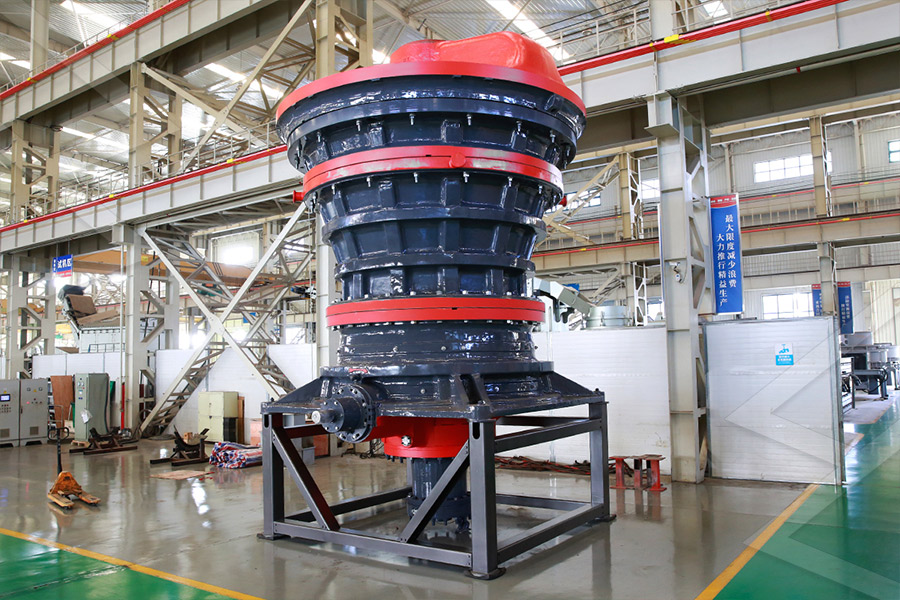

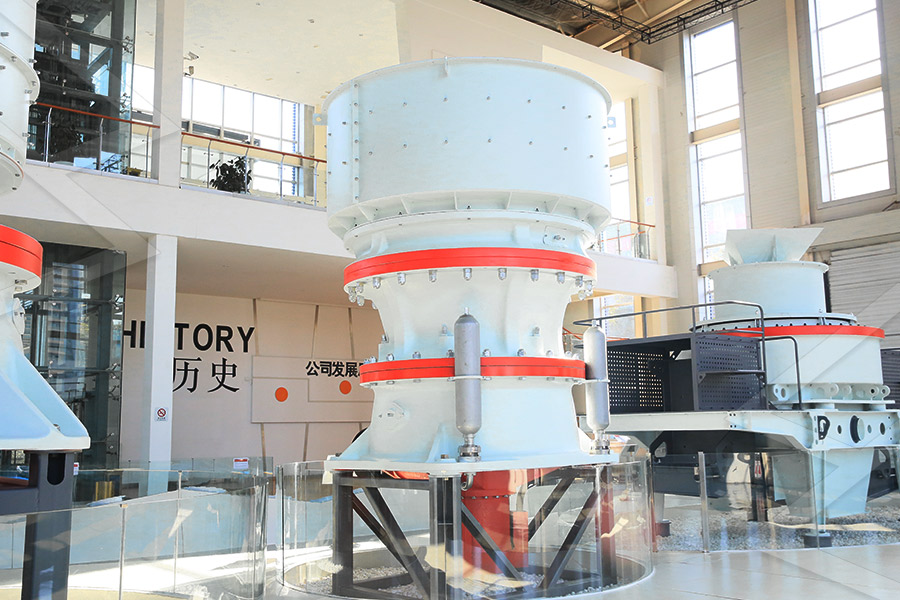

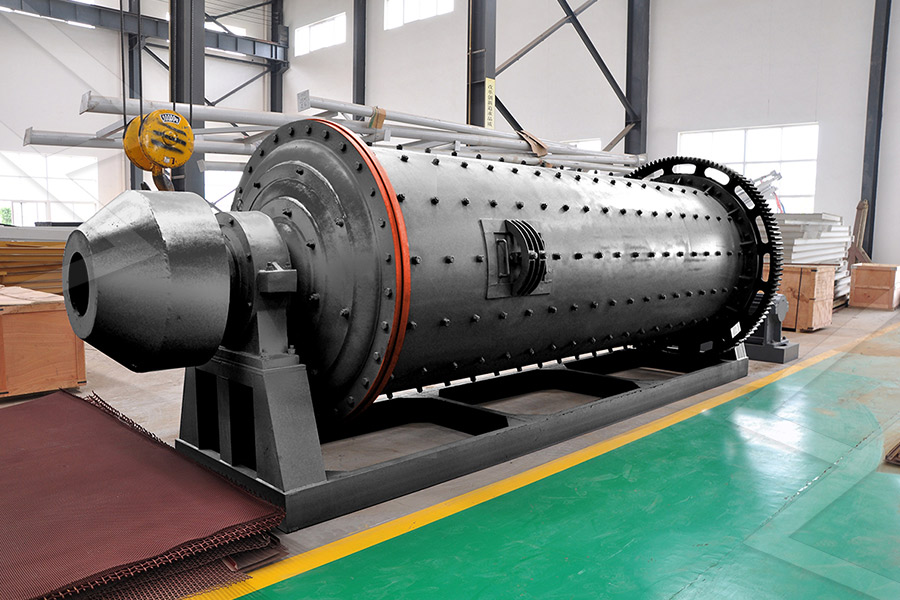

2020年9月23日 Gravity concentration or in other word this process is also known as gravity separation This process is applicable for those ores in which principle metals have higher density as compared to their gangue and other earthy impurities The specific gravity of iron ore is higher than its gangue The specific gravity of common iron ores are2020年4月1日 Preheat treatment of chromite ore plays a vital role in gravity separation The optimized tabling conditions suggested by BBD are 8° tilt angle, 4 L∙min1 water flow rate and temperature for Process optimization of a chrome ore gravity concentration 2008年1月1日 Gravity separation by jigging to produce highergrade iron ore products has been practiced for many decades (Miller 1991(Miller , 2003 and is a potential technology for beneficiating difficultto (PDF) Effective Beneficiation of Low Grade Iron Ore2022年1月1日 The ore is mainly composed of magnetite, hematite, martite, and quartz It is very difficult to produce a high quality iron ore concentrate by magnetic separation alone for this type of iron ore The feed ore is first ground using ball mills down to about 90% −75 micron particle sizePhysical separation of iron ore: magnetic separation

Comminution and classification technologies of iron ore

2022年1月1日 Iron ore is one of the main raw materials to make steel About 98% of the mined iron ore is used to make steel either by the blast furnace—basic oxygen furnace (BFBOF) route or through the electrical arc furnace (EAF) route The majority of world crude steel is made from the BFBOF route2020年12月1日 In the present study a detailed characterization followed by beneficiation of low grade iron ore was studied The Run of Mine (ROM) sample assayed 2191 % Fe, which is very low grade in nature(PDF) Beneficiation and flowsheet development of a low grade iron ore