Bond Mill Work Index Database Jktech Benification Of Iron Ore Youtube

.jpg)

SAG Mill Design and Benchmarking Using Trends in the

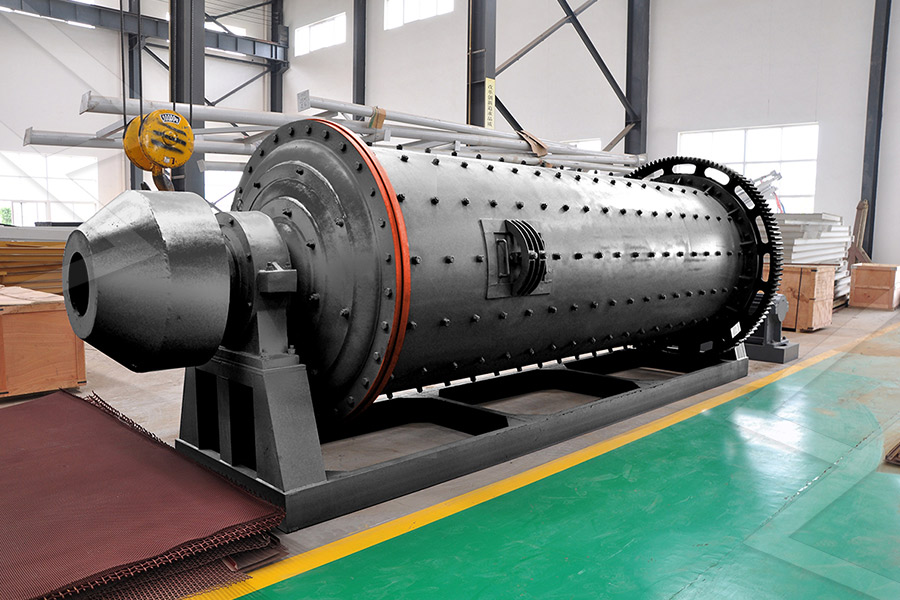

This paper describes some of the major trends in JKTech’s database of comminution circuit surveys, and how the variability inherent in data obtained from productionscale mills can be An improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard Comminution testing JKTech University of QueenslandSince its introduction in the 1960s, the Bond Ball Mill Work Index (BBMWi) parameter has been extensively used in predicting ball mill power draw Use of Work Index Along with JK Bond Ball Mill Test JKTechThe relationship between the Bond rod mill work index and Bond ball mill work index tells a lot about the difference in grindability, and hence energy requirements, between coarse and fine Bond Work Index an overview ScienceDirect Topics

.jpg)

Estimation methodology for Bond ball mill work index

2023年10月1日 The Bond ball mill work index is an expression of the material’s resistance to ground and a measure of the grinding efficiency The test is a standardized methodology that 2021年6月17日 The Bond work index most commonly referred to is the BBM work index This value is obtained in a 12” × 12” laboratory mill running at 70 rpm, with rounded inner edges and without lifters The grinding charge is comprised Variability Study of Bond Work Index and 2021年10月28日 A Bond rod mill work index test (BRMWI) is a standard test for determining the rod mill work index of an ore sample [21] The BRMWI is a measure of the resistance of the Using Rock Geomechanical Characteristics to Estimate Bond Work Index 2009年1月1日 Starting from the firstorder grinding kinetics defined by means of the Bond ball mill, this paper discusses a simplified procedure for a rapid determination of the work index by Procedure for determination of ball Bond work index in the

.jpg)

SGS MINERALS SERVICES – T3 SGS 960 112009

2024年6月19日 BOND ROD MILL GRINDABILITY TEST The Bond Rod Mill Grindability Test is also performed according to the original Bond procedure It requires 15 kg of minus ½ mesh 2018年4月28日 Bond work index and magnetite percent were investigated in the 430 blasts in the mine This investigation not only confirmed the small scale blasting results, but also Effect of magnetite content on Bond work index and 2013年7月15日 When Erf/Erp is greater than 129, the work index increases as the product size decreases, and when Erf/Erp is less than 129 the work index decreases Eq (8) suggests that a standard work index Wi100, or the work Bond Work Index FormulaEquation1 A grindability measurement made in a laboratory work index apparatus, such as a ball mill work index (WiBM) or a rod mill work index (WiRM) 3 An operating work index (WiO): A measurement of a specific energy consumption and size reduction in an operating plant 4 A generic work index that represents an intrinsic ore breakage characteristic BOND'S WORK INDEX: WHAT IT IS AND WHAT IT ISN'T

.jpg)

Article Determination of Work Index of Muro Iron Ore

The value of the work index of Muro iron ore is within the limit of work index of iron ore quoted in literatures Keywords: Bond’s Equation, Grinding, Iron Ore, Marble, Size2021年1月14日 Key Words: Comminution Tests, Bond Work Indices, JKTech, Grinding Mill Design, Database, Ore Hardness Measurements, JK Drop Weight Test, SAGDesign Test • SAGDesign (SAG to T80 12 M followed by Bond BM Wi on SAG ground ore) • Bond Ball Mill Work Index (Crushed Feed) • Specific Gravity (part of the SAGDesign test) Comparison of Ore Hardness Measurements for 2021年1月1日 The recommendations are given for selecting the Bond mill revolutions in the first milling cycle for apatite–nepheline, copper–nickel and iron ore for the sieve size 106 μparative assessment of the Bond Ball Mill Work Index tests2023年1月1日 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and Iron ore beneficiation: an overview ScienceDirect

Comparison of the Different Ways of the Ball Bond Work Index

2019年9月12日 When designing concentrating plants, the selection of the technological comminution scheme for beneficiation, the type, quantity and size of the equipment, the determination of optimal grinding regimes and the calculation of equipment loads are carried out by preliminary studies of grinding in semiindustrial or laboratory conditions Semiindustrial An improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size (100% passing 335 mm) as the Bond Ball Mill Work Index test The test requires Comminution testing JKTech University of Queensland2017年1月1日 The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test Its value constitutes ore characteristic and is used for industrial A quick method for bond work index approximate value determination2010年1月1日 The bond work index test obtained high work index 5260 kwh/t and consumed power 1172 kwh/t to grind one ton of low grade iron ore and this attributed to the high concentration and hardness of Determination of Bond index of BirninGwari

Characterization and Bond Work Index Determination of Low

: In this study, the mineralogical, chemical characterization and physical properties of Sudanese iron ore in west of Omdurman city were studied using microscopic investigations, Xray Diffraction analysis (XRD), Xray Fluorescence (XRF) analysis, Atomic Absorption Spectrophotometer analysis (AAS) and the test of Bulk density As well as, the Bond Work Index (BWI) and 2020年6月8日 The bond work index test obtained high work index 5260 kwh/t and consumed power 1172 kwh/t to grind one ton of low grade iron ore and this attributed to the high concentration and hardness of Characterization and Bond Work Index 2014年4月3日 Fig 3 Types of processing ores The wet processing (Fig 4) is normally practiced for low / medium grade (60 % Fe to 63 % Fe) hematite iron ore The wet process consists of multistage crushing followed by different stages of washing in the form of scrubbing and / or screening, and classification etc, but the advantage is only partial removal of adhered alumina and free Beneficiation of Iron Ores IspatGuruJKTech Comminution Analyst Matt Weier will be travelling to Santiago for Procemin 2018 to present his paper Accuracy of the Bond Ball Mill Test and Its Implications ProceminGeomet is a forum where professionals can learn and analyse best practices and innovations related to mineral processing and geometallurgy in metallic and nonmetallic miningJKTech Comminution Analyst travels to Santiago to present

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 The final stage in iron ore processing is ironmaking, where the iron ore is transformed into molten iron through a process called reduction The most common method of ironmaking is the blast furnace route In a blast furnace, iron ore, coke (carbon), and fluxes (limestone or dolomite) are loaded into the furnace from the top2016年3月31日 Commentary on the apparatus of the Bond rod mill Work Index by Alex Doll December, 2015 alexdoll@sagmilling The Bond “Third Theory” of comminution was originally divided into three size classes reflecting the varieties of comminution equipment common during the time period when Bond (and his collaborators) were gathering the Bond Rod Mill Work Index Equipment Apparatus Review2024年6月19日 BOND ROD MILL GRINDABILITY TEST The Bond Rod Mill Grindability Test is also performed according to the original Bond procedure It requires 15 kg of minus ½ mesh material that is preferably prepared at the testing facility The Bond Rod Work Index has been widely used for rod mill sizing JKTECH DROPWEIGH TEST ore under a range of impact SGS MINERALS SERVICES – T3 SGS 960 112009an average work index of 155 kWh/t A very broad range of results was received, characterising the ‘standard ore’ from medium to very hard A disappointing result considering the reliance on this test globally for design and optimisation An improved method using less mass compared to the Bond Ball Mill Work Index testJK Bond Ball Mill Test JKTech

.jpg)

Characterization and Bond Work Index Determination of

2020年5月29日 relationship to Bond work index and the energy consumption ,which increasing of hardness value causes increasing in Bond work index and the consumed energy [6] Berry and Bruce (1966) discovered new method for determining the work index, the concept of this method depended on the use of a reference ore of known work index[7] Iron ore is one of 2009年1月1日 The Bond ball mill grindability test is run in a laboratory until a circulating load of 250% is developed It provides the Bond Ball Mill Work Index which expresses the resistance of material to ball millingThis happens after 7–10 grinding cycles, which shows that the procedure is a lengthy and complex one and is therefore susceptible to procedural errorsProcedure for determination of ball Bond work index in the 2015年11月23日 Relation of Bond rod mill work index and crushing work index Similar to the ball mill work index, the rod mill work index is a tumbling test that includes both attrition and abrasion breakage mechanisms Unlike the ball mill Compare and Understand Rod/Ball/Impact 2021年6月17日 It is a wellknown fact that the value of the Bond work index (wi) for a given ore varies along with the grinding size In this study, a variability bysis is carried out with the Bond standard grindability tests on different critical Variability Study of Bond Work Index and

.jpg)

Characterization and Comminution Studies of LowGrade Indian Iron

2019年1月31日 Banded hematite quartzite (BHQ) and banded hematite jasper (BHJ) ores represent a promising potential iron ore resource in the near future The hematite and quartz in BHQ and the hematite and jasper in BHJ are closely related and require fine grinding for the liberation of hematite phases The present study investigates the mineralogical features and The commonly used grindability tests included in the database are the Bond work indices for ball milling, rod milling and crushing; the drop weight test results A, b, A×b, DWi, Mia, Mic, Mih and (PDF) BOND'S WORK INDEX: WHAT IT IS AND WHAT IT 2018年4月28日 Grinding is one of the most costly operations in the mechanical breaking and mining Determination of the breakage characteristics and preconditioning is important to increase the grinding efficiency Investigations of the seismic, mechanical and breakage properties of iron oxides are very important parameters for investigating the rock fragmentation by blasting and Effect of magnetite content on Bond work index and The Bond Work Index of a material is defined as the required energy to reduce one ton of that material from a notional infinite size to a P80 size of 100 µm, the Bond grindability test is conducted to determine the Bond work index (Wi) via Standard Bond Ball Mill which having the dimensions D×L=305×305 mm and a speed revolution of 70 min−1 Characterization and Bond Work Index Determination of Low

Development of process for beneficiation of lowgrade

2018年12月19日 to modal analysis of liberated ore mineral, liberated gangue mineral and interlocked grains Bond work index (Standard FC Bond work index) The crushed sample that was smaller than 335 mm — smaller than 6 mesh — was subjected to Bond work index studies For the grindability test, the standard procedure was followed to find2010年7月20日 In this study, the Bond work index of Birnin Gwari iron ore in northern Nigeria is determined using modified Bond’s method using ‘reference ore’ Samples of iron ore were sourced using random method, reference minerals; marble and granite of known weight and iron ore of known weight were ground using the laboratory ball mill grinding Determination of Bond index of Birnin Gwari Iron Ore in 2018年9月17日 3 Introduction Iron is the fourth most abundant mineral on earth having a reserve of 170 billion tonnes of crude iron ore Iron steel is the driving force behind industrial development in any country The mining of iron ore, an essential raw material for Iron Steel Industry, is arguably of prime importance among all mining activities undertaken by any Seminar on iron ore beneficiation in india PPT SlideShare2013年7月15日 When Erf/Erp is greater than 129, the work index increases as the product size decreases, and when Erf/Erp is less than 129 the work index decreases Eq (8) suggests that a standard work index Wi100, or the work Bond Work Index FormulaEquation

BOND'S WORK INDEX: WHAT IT IS AND WHAT IT ISN'T

1 A grindability measurement made in a laboratory work index apparatus, such as a ball mill work index (WiBM) or a rod mill work index (WiRM) 3 An operating work index (WiO): A measurement of a specific energy consumption and size reduction in an operating plant 4 A generic work index that represents an intrinsic ore breakage characteristic The value of the work index of Muro iron ore is within the limit of work index of iron ore quoted in literatures Keywords: Bond’s Equation, Grinding, Iron Ore, Marble, SizeArticle Determination of Work Index of Muro Iron Ore 2021年1月14日 Key Words: Comminution Tests, Bond Work Indices, JKTech, Grinding Mill Design, Database, Ore Hardness Measurements, JK Drop Weight Test, SAGDesign Test • SAGDesign (SAG to T80 12 M followed by Bond BM Wi on SAG ground ore) • Bond Ball Mill Work Index (Crushed Feed) • Specific Gravity (part of the SAGDesign test) Comparison of Ore Hardness Measurements for 2021年1月1日 The recommendations are given for selecting the Bond mill revolutions in the first milling cycle for apatite–nepheline, copper–nickel and iron ore for the sieve size 106 μparative assessment of the Bond Ball Mill Work Index tests

Iron ore beneficiation: an overview ScienceDirect

2023年1月1日 The quality of Indian iron ore resources is generally good with high iron content and high percentage of lumpy ore More than 85% of the hematite ore reserves are of medium to highgrade (+62% Fe) and are directly used in blast furnace and in directreduced iron (DRI) plants in the form of sized lump ore, agglomerated sinter, and agglomerated pellets (Iron and 2019年9月12日 When designing concentrating plants, the selection of the technological comminution scheme for beneficiation, the type, quantity and size of the equipment, the determination of optimal grinding regimes and the calculation of equipment loads are carried out by preliminary studies of grinding in semiindustrial or laboratory conditions Semiindustrial Comparison of the Different Ways of the Ball Bond Work Index An improved method using less mass compared to the Bond Ball Mill Work Index test The JK Bond Ball Mill (JKBBM) test, is a locked cycle grindability test conducted using a standard laboratory Bond Ball Mill with the same steel ball charge and material feed size (100% passing 335 mm) as the Bond Ball Mill Work Index test The test requires Comminution testing JKTech University of Queensland2017年1月1日 The Bond work index is a measure of ore resistance to crushing and grinding and is determined using the Bond grindability test Its value constitutes ore characteristic and is used for industrial A quick method for bond work index approximate value determination